~ WEG motor designed to start hydrogen-ready turbines ~

The share of hydrogen in Europe’s energy mix is expected to grow from less than two per cent, to over 13 per cent by 2050. Offering drastically reduced carbon emissions when burned for fuel, hydrogen is a key part of achieving Europe’s clean energy ambitions. When a global company was looking for a way to start gas turbines, they turned to WEG Italia for its reliable motors and innovative engineering capabilities.

In 2016, WEG was approached by a customer trying to achieve a specific goal: developing a system capable of starting a gas turbine.

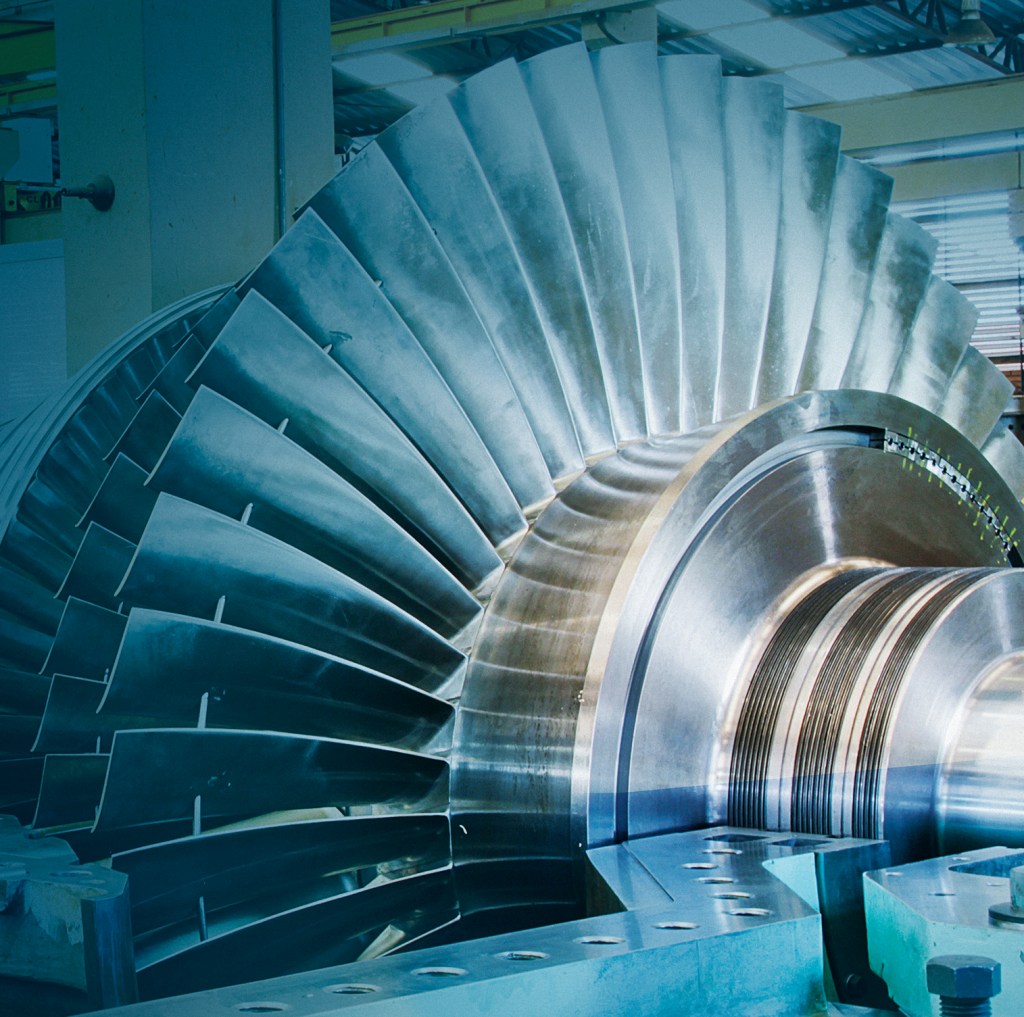

A gas turbine is made up of three main sections, a compressor, a combustion system and a turbine. As it spins, air is drawn into the compressor, pressurised and forced into the combustion chamber, where fuel is injected and ignited. Burning at temperatures of more than 1000 degrees Celsius, this combustion creates a hot, high pressure gas stream that expands through the turbine. The force of the expanding gas spins the turbine blades, which both spin a generator to produce electricity and drive the compressor to draw in more air.

Once it is running continuously, the gas turbine is self-sustaining. However, to get to that point, the compressor must reach a certain speed, known as the firing point. For that, initial momentum from a motor is needed.

A complex brief

For WEG Italia’s engineering department, there were numerous challenges to consider when designing this motor system. The first was designing a system that could run up to the very high speeds necessary to reach the firing point. Gas turbines can run as quickly as 10,000rpm, and the firing point is usually above 50 per cent of full operating speed. The WEG system was to use an asynchronous motor, which further complicated matters — it is more difficult to make asynchronous motors reach such high speeds.

The second challenge for WEG’s engineers was reliability. For a critical application like a gas turbine, reliability is paramount. The gas turbines using this motor system would power complete plants, or even cities. As the motor is the only way to start the turbine, if it didn’t run, or couldn’t reach the necessary speed, whole plants or thousands of homes would be without electricity. In this kind of situation, the reliability, safety, and efficiency that are the hallmark of all WEG’s motors are essential.

Thirdly, gas turbines are classified as hazardous areas. This meant that the finished system would need to adhere to the highest safety standards. Furthermore, as the client was a global energy technology company, flexibility was key. The turbines could be installed anywhere gas is used, so the system needed to be able to pass, or adapt to, a whole host of safety regulations. WEG’s experience in motors for hazardous areas and of working around the world would be invaluable.

With so many obstacles facing them, WEG Italy’s engineering team had a huge task ahead.

“Whatever a customer’s application, WEG’s engineers approach the problem with an open-mind and a determination to find the most effective and efficient solution,” explained Fabrizio Arosio, sales account manager at WEG Italia. “Designing the motor system and coming to a commercial agreement took almost two years, and it wasn’t until 2018 that work on the first batch of projects could begin.

“Ultimately, WEG supplied a variable frequency drive integrated into an electrical panel with electric motors,” continued Arosio. “WEG has devoted special attention to design suitable motors for the oil and gas industry. Operational reliability coupled with flexible mechanical design mean our motors have low downtime and service maintenance.”

Supporting the gas industry

WEG’s mix of expert engineers, industry knowledge, continually updated manufacturing methods, and innovative research and development, make them the perfect supplier to the oil and gas industry — capable of rising to the challenge of any operating environment, no matter how demanding.

The motor has been successfully installed with the first gas turbine and is now generating electricity. As the customer replaces more gas turbines across the globe with this new model, WEG will continue to supply its bespoke starting motor system. While the first stage of the project is complete, WEG’s engineers will carry on developing and improving the system, aiming for maximum efficiency.

“Despite a very challenging brief, WEG succeeded in finding a solution to fulfil the customer’s needs. The motor can reach the very high speeds necessary to start the turbine while retaining WEG’s characteristic efficiency,” commented Arosio. “Each installation has its own set of unique variables. The WEG team must consider the environment, differences between technical drawings and reality, and unforeseen problems. Thanks to team’s expertise, the motor is now running successfully.”

As this customer has shown, with the help of WEG motors it is possible to start preparing for the gas industry of tomorrow. Hydrogen will play a huge part in reducing the carbon emissions of using gas to generate electricity, and by making your infrastructure hydrogen-ready now, futureproofing is possible. The reliability and efficiency of WEG motors make them ideal for the demanding environments of the oil and gas industries, while it’s the expertise and determination of WEG’s engineers that ensure the project will be a success no matter how challenging it may appear.

For more information on what WEG has to offer the gas industry, click here. To explore WEG’s full range of motors, follow this link.