Category: Opinion piece

-

Revolutionising efficiency: WEG’s breakthrough W80 AXgen axial flux motor

For more than a century, industrial motors have remained largely unchanged in their core design, relying on radial flux technology to power everything from manufacturing lines to heavy-duty machinery. While this approach has been refined over time, the industry has faced a fundamental challenge: how to make motors more compact, efficient and adaptable — without…

-

Driving growth in Central Europe

Since its official launch in March 2021, WEG Poland has emerged as a dynamic force in the motion and drive systems industry. Strategically positioned in southern Poland, near Kraków, this organisation plays a vital role in supporting various industries across Poland and bordering countries, including Slovakia and the Czech Republic. Guided by General Sales Manager…

-

Bringing legacy DC motors into the digital age

“They don’t make them like they used to.” This phrase rings especially true in heavy industry, where DC motors installed decades ago still deliver reliable performance. But in the face of increasing digitalisation, the challenge isn’t whether the motors can keep going — it’s whether their supporting infrastructure can keep up. Here, Andrea Verzaglia, Product…

-

Dual strategies for Industry 4.0

Asset and equipment management is being revolutionised by digital industrial solutions. However, for WEG — the global industrial equipment manufacturer — Industry 4.0 is not just a strategy for product development, but for internal processes too. Here, Mateus Nicoladelli de Oliveira, from the WEG digital solutions team and Jesus Angel Rivas Moro of WEG Iberia…

-

Specifying a gear unit

A species of British insects, called planthoppers, have a row of small teeth on each leg that interlock together. As the planthopper jumps, the teeth ensure its legs rotate and extend at the same time. Essentially, the insect has gears. Mimicking nature, industrial gears are essential for transferring power and motion, but in industry, the…

-

Where do drives support energy efficiency?

Supporting environmental compliance in fans, pumps and compressors Today, the most common use of drives in industrial environments is for the control of fans, pumps and compressors. In fact, these applications account for about 75 per cent of all drives operating globally. Here, Marek Lukaszczyk, European and Middle East marketing manager at motor and drive…

-

VSDs vs. soft starters: A guide to choosing the right efficiency equipment

Approximately eight billion electric motors are in operation in Europe, consuming nearly half of all the continent’s electricity. Variable speed drives (VSDs) and soft starters provide ways to reduce the energy consumption of a motor by providing operators with control over their power. But which is the most appropriate choice? Here, Marek Lukaszczyk of WEG…

-

Energy mapping for food processors: Identifying pain points in food manufacturing

Promising cheaper and more energy efficient cooking than a traditional oven, air fryers have been flying off the shelves in the past year. For the food processing industry however, cutting energy costs isn’t as straightforward as switching to smaller equipment. With energy now accounting for up to ten per cent of total costs for industry…

-

Transforming industry with digital technology

Digital technologies are accelerating innovation and efficiency at an unprecedented scale. Improved accessibility and affordability have made it simpler than ever to implement advanced digital systems to improve industrial processes. Here, Trenton Roncato Juraszek, mechanical project analyst at leading global motor and drive manufacturer WEG, discusses the importance of digitalisation in industry, and how it…

-

Boosting efficiency in manufacturing environments

According to The Times, 20 per cent of business owners expect the UK’s cost of living crisis to hit them harder than the COVID pandemic. The pressure is on all businesses, including manufacturers, to achieve greater cost-efficiency throughout their operations, well into the future. Here, Marek Lukaszczyk, European and Middle East marketing manager at motors…

-

The route to Net Zero

Manufacturers and end users of motors and drives need to get onboard with ambitious zero emission targets pledged by governments around the world. But, it’s estimated that nearly half of the world’s energy is consumed by electric motors. Here, Marek Lukaszczyk, European and Middle East marketing manager at global motors and drives manufacturer WEG explains…

-

Digitalisation in hazardous industries

Industries operating in hazardous areas must consider standard safety practices and ensure all equipment meets the requirements for flammable or explosive atmospheres. Effective monitoring, predictive maintenance and rapid response to failure is crucial for engineers managing these assets. Here, Marek Lukaszczyk, European and Middle East marketing manager at global motor manufacturer WEG, discusses how digitalisation…

-

Three digital trends for VSDs

According to Pricewaterhouse Coopers (PwC), 98 per cent of industrial companies in Europe expect to increase their efficiency with digital technologies, predictive maintenance or augmented reality (AR) solutions. But where do variable speed drives (VSDs) fit into this? Here, Marek Lukaszczyk, European and Middle East marketing manager at VSD specialist WEG, explains three ways that…

-

Increasing profit margins through energy efficiency

~ Can correct motor management cut costs in food and beverage production ~ With growing pressure on the food industry’s profit margins, companies must look to reduce manufacturing costs wherever possible. The food industry is incredibly energy intensive, accounting for around 30 per cent of global energy consumption As a result, improving efficiency offers an…

-

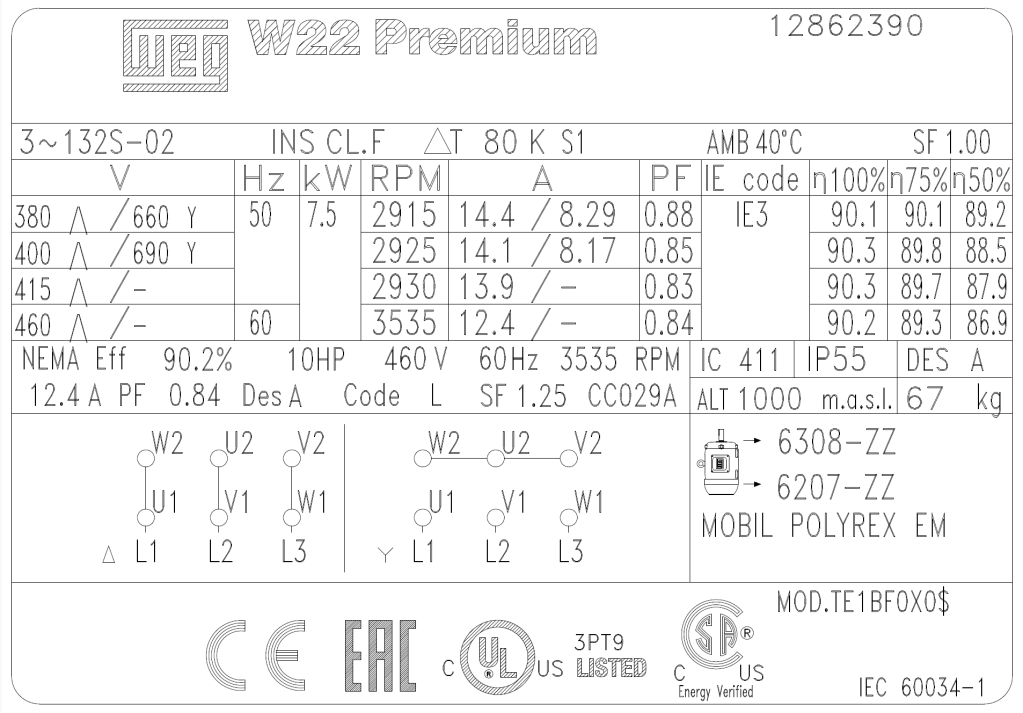

How to read a motor nameplate

Electric motors sold in most countries are fitted with a nameplate displaying important operating data. Being able to read and understand these nameplates can help engineers select the most appropriate motor for an application, but they can be complex to decode. Here, Loic Kentrotis, marketing manager at leading motor manufacturer WEG France SAS discusses how…

-

Motor legislation 2023: What happens next?

Electric motors account for approximately 45 per cent of power consumption worldwide, with over 8 billion motors used in Europe alone. Updated European regulations for ecodesign came into effect in July 2021, setting out new energy efficiency standards for motors and drives. The second stage of the legislation changes is set to commence on July…

-

Why VSDs are essential for HVAC applications

The International Energy Agency (IEA) projects that doubling the energy efficiency of air conditioning by 2050 would prevent global electricity demand from growing by 1,300 gigawatts and save up to 2.9 trillion USD. But, how can this energy saving be achieved? One way to make heating, ventilation and air-conditioning (HVAC) systems more efficient is through…

-

Digitalisation for the energy market

According to the European Union (EU), renewables overtook fossil fuels to become the number one energy source in the EU in 2020, producing 38 percent of the total energy generated. Digitalisation can be a valuable tool in a constantly evolving energy landscape, but how can operations in this sector effectively incorporate digital technologies? Here, Javier…