Category: Case studies

-

WEG achieves 33 per cent reduction of losses with digital maintenance tools

~ Industry 4.0 for asset management ~ Fuelled by fierce demand for faster and more efficient production, growth in Industry 4.0 spend is predicted to reach $300 billion USD by 2023. This data comes from IoT Analytic’s Industry 4.0 and Smart Manufacturing report, which states predictive maintenance technologies are among the top Industry 4.0 use…

-

WEG supplies motors for world’s most powerful test rig

WEG, a leading global motor manufacturer, will supply two drive motors for the world’s most powerful test rig. This test rig is being developed by Danish wind turbine test specialist, R&D Test Systems, a company that develops projects and validates new technology with turnkey test systems. With two 30 MW motors from WEG, the test…

-

Energy-efficient motors power Hong Kong’s sustainable development

CBV, in partnership with motor and drive manufacturer WEG, has contributed to developing a self-sustaining waste to energy (WTE) island for Hong Kong’s residual waste. It is estimated the island will save 440,000 tonnes of carbon emissions per year, the equivalent of the yearly carbon emissions produced by 2.2 million gas-based cars.

-

Cleaning up the world’s shipping industry

Each year, industrial ships are responsible for consuming around 370 million tonnes of fuel. In fact, a single ship can emit as much carbon dioxide as two million cars. As a solution, electrified shipping is beginning to make waves. Exploiting improvements in battery design and automation from technology experts, the sector is estimated to reach…

-

WEG supplies for bespoke automated cart system

The humble potato has been voted as the UK’s favourite vegetable, according to a new public poll. But do you know how they end up on your plate? Here’s how industrial motor manufacturer, WEG has partnered with Technidrive to provide equipment for an automated cart system for plant propagator, John Gabbie & Sons, to help…

-

A cut above the rest

~ WEG supplies for unique meat processing line ~ Cumbersome lines are synonymous in food processing, as there is often little to no automation involved, making the operation awkward and difficult. Most lines lack technological innovation, but the industry is beginning to move to automated and robot driven processes. Here’s how, industrial motor manufacturer, WEG…

-

Powering tomorrow’s hydraulic systems

The global hydraulics market size is expected to reach USD 42.1 billion by 2025, growing at a CAGR of 2.4 per cent. While hydraulics have traditionally been renowned for power, strength, durability and control, the need for more energy efficient systems is driving innovation in the sector. One such innovator is Oilmek AB, a Swedish…

-

Reliably converting blast furnace gas into electricity

The Knippegroen power plant — commissioned by Electrabel in December 2010 — is located on the site of the steel producer ArcelorMittal in Ghent, Belgium. The power plant serves two needs: to meet the large long-term electricity demands of the steel company and to provide conversion into electricity for the residual gases that are formed…

-

WEG permanent magnet motor saves energy for Orleplast

Global motor manufacturer, WEG has successfully completed an energy saving project for Orleplast, a leading packaging manufacturer based in Brazil. With the initial goal of achieving greater productivity, Orleplast took the opportunity to invest in more efficient equipment for its site, turning to the experts at WEG’s Energy Efficiency Business Centre for support. Orleplast is…

-

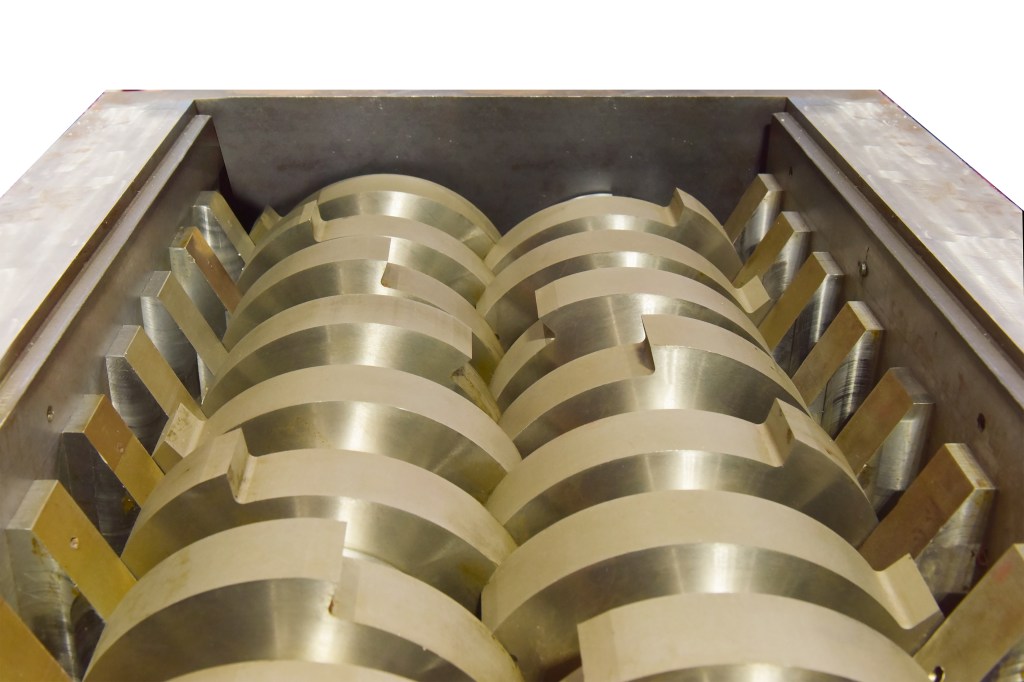

Using VSDs for shredder control

~ How VSDs can increase throughput and efficiency in shredding applications ~ We’ve all faced a situation where our handy office shredder grinds to a halt when it becomes jammed or overloaded. In this scenario, you can usually press the reverse button to remove the blockage. For larger shredders in industrial applications, such as those…

-

WEG supplies for world’s largest irrigation project

The quality of agricultural land in India varies from region to region, with some parts being quite arid. In fact, in parts of the country where land requires water levels of up to 800m, just 200m of water is present. Without water facilities nearby, these low water levels are not sufficient to irrigate this dry…

-

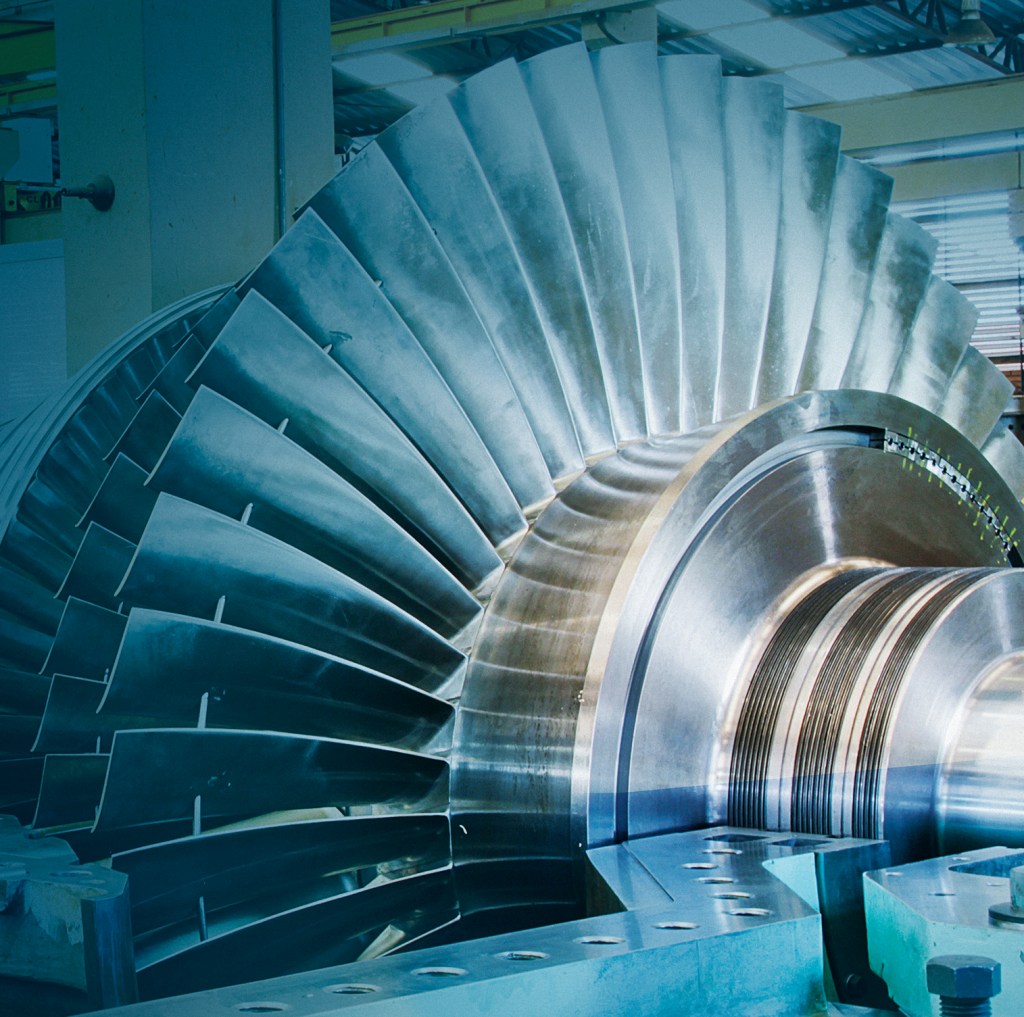

Powering the future

~ WEG motor designed to start hydrogen-ready turbines ~ The share of hydrogen in Europe’s energy mix is expected to grow from less than two per cent, to over 13 per cent by 2050. Offering drastically reduced carbon emissions when burned for fuel, hydrogen is a key part of achieving Europe’s clean energy ambitions. When…

-

Container crane improves efficiency at freight terminal

~ WEG and Nedcranes install new crane at Railport Brabant ~ According to Inbound Logistics 2019 Global Logistics Guide, the Netherlands is one of the world’s strongest logistics hubs for global trade connections. However, with around three quarters of freight transport managed by road, the thriving freight industry is under pressure to improve the sustainability…

-

Reaching new heights

An automated warehouse is a breath-taking sight, as reams of pallets are automatically scanned and retrieved for delivery. But not all automation systems are made to endure extreme environments. Here’s how Technidrive Ltd and WEG partnered to help Moffett, an automated storage firm, design a vertical lift for extreme temperatures.

-

Improving jaw crusher safety

According to the Health and Safety Executive’s guidance for the safe operation and use of mobile jaw crushers, equipment operators may be subject to multiple risks including exposure to dust, noise, whole body vibration and being struck by objects ejected from the crusher. Here’s how, WEG’s premier distributor Technidrive, developed an energy efficient automatic jaw…

-

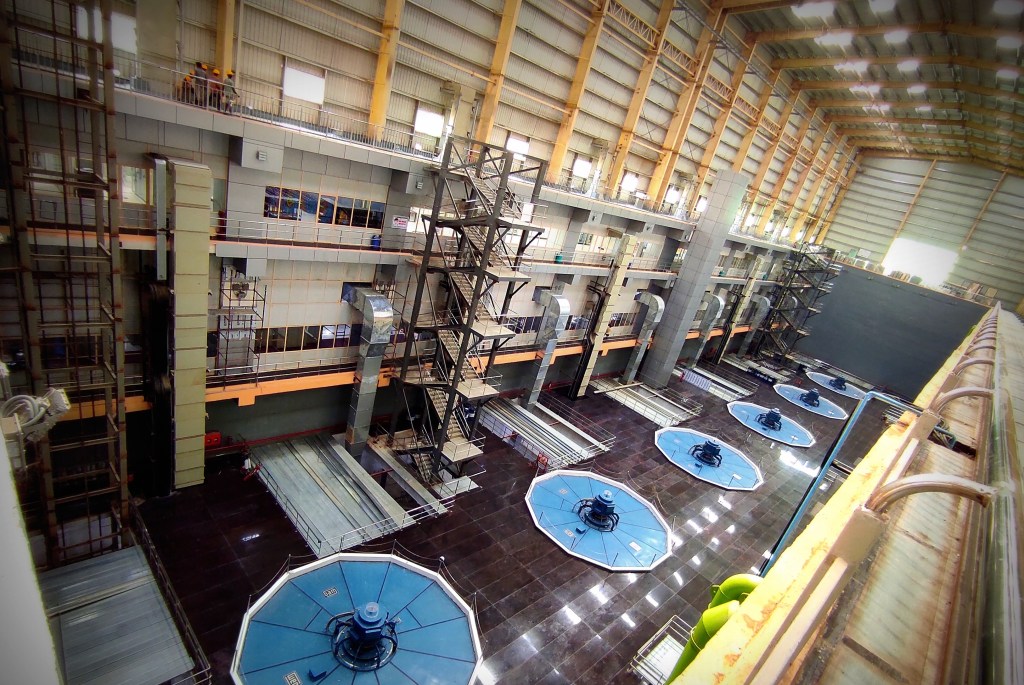

WEG products drive the world’s largest lift irrigation project

To address water shortages in Telangana, India, electric motor manufacturer, WEG has supplied 14 262-ton electric motors for the world’s largest life irrigation project, the Kaleshwaram Lift Irrigation Scheme (KLIS). Following two years of construction, the project was completed in June, 2020. The project is the largest contract WEG India has completed for the water…

-

WEG partner scoops World Oil Awards win

Global energy leader, Technip FMC, has won the Best EOR Technology Award at the 2020 World Oil Awards ceremony. Technip FMC’s award-winning project saw the company partner with motor and drive manufacturer, WEG to help design a subsea power distribution station.