France is one of the largest producers of electricity, with EDF, Engie and Total all major players in the energy sector. Here, Yves Jamet, marketing manager at WEG France SAS, a leading global manufacturer of motors and drives, explains how industrial businesses can contribute to France’s energy efficiency targets by opting for a motor with a white certificate.

Although Climate Action Network (CAN) Europe recognises France as a leading nation in Europe’s climate change fight, more needs to be done. Progress to reduce energy consumption has been slow and France needs to tackle its high emissions, especially in the transport, agriculture and food sectors. But, what can French industrial businesses do to contribute to these energy savings?

Energy efficiency obligation schemes, or more specifically, the white certificate scheme has been one of the main regulatory tools in the nation’s energy savings mission. Having also been introduced in other European countries such as the UK and Italy, the French white certificate scheme is now in its fourth period.

The white certificate is based on an obligation to achieve energy savings imposed by the public authorities on energy sellers called obligated parties. These sellers are thus encouraged to actively promote energy efficiency to their customers and other energy consumers, such as households, local authorities or professionals.

There are two types of actions:

- Standard operations: A catalog of standardised, reproducible operations that make it possible to reach diffuse sources of savings has gradually been established. These operations are listed in the form of sheets that make it possible to quickly calculate the number of cumulative kilowatt hour cumac (kWh cumac) resulting from the implementation of a standardised operation on a flat-rate basis. The kWh cumac is the unit of energy savings recorded in kWh of final energy, cumulated over the lifetime of the measurement and updated.

- Specific transactions or non-standard transactions: These are complex because they are often linked to industrial processes but have a high potential for energy savings. Companies specialising in energy efficiency can use a feasibility audit to identify the potential for energy savings in these non-standard operations.

While this scheme has been around since 2006, the majority of white certificate savings have been undertaken in the residential sector with heating device replacement dominating in the French market.

With approximately 63 per cent of the electrical consumption absorbed by electric motors, industrial businesses can significantly improve the energy efficiency of their plant, by opting for an energy saving motor. With the increasing importance of establishing lasting cooperation between end-use energy efficiency and the energy market, opting for an energy efficient motor with a white certificate ensures that your energy supplier is also on board.

An energy efficiency project, such as installing a new motor, must first go through an accreditation process. Your energy supplier is obliged to undertake energy efficiency measures that are consistent with a pre-defined percentage of their annual energy deliverance. These certificates can be traded to ensure that energy companies can fulfil their obliged energy savings. However, if energy producers fail to meet the required targets, they must pay a financial penalty of 2c€ per missing white certificate.

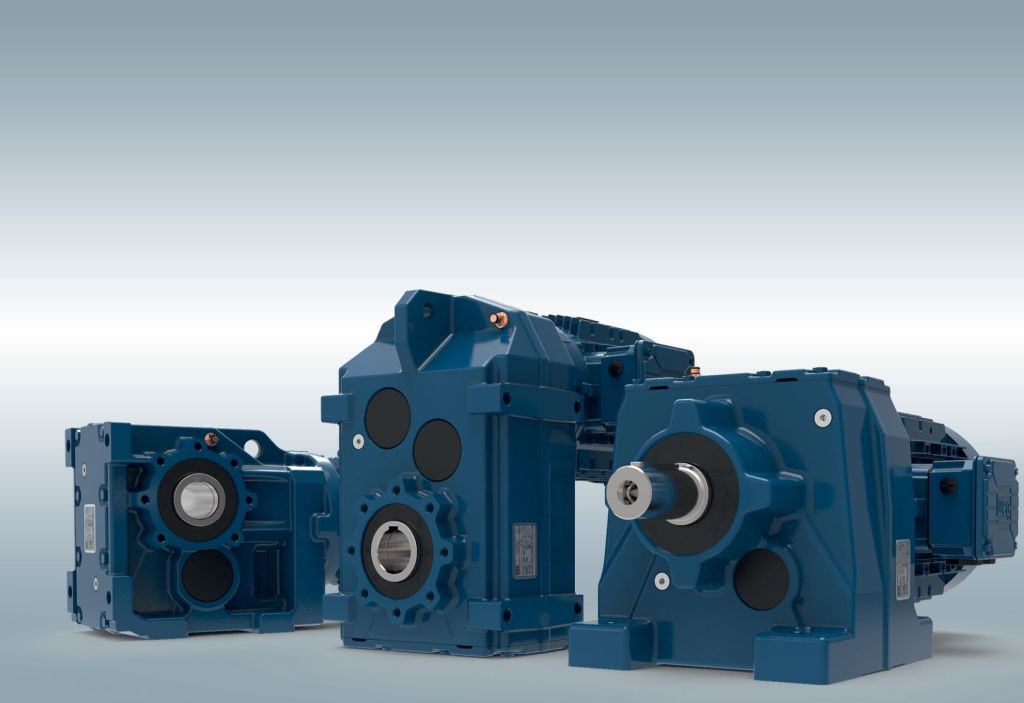

WEG’s W22 Magnet motor for example, features rotors with permanent magnets, which meets the requirements defined by the Energy Saving Certificate No. IND-UT-114. This technology provides the motor with significant advantages such as higher efficiency and a greater power density per frame. The W22 Magnet motor comes in IE4 super premium and IE5 ultra-premium efficiency ratings. The white certificate system that accompanies this motor, allows the energy supplier to deliver a premium when the user invests in a LV permanent magnet motor up to a power of 1 MW.

Businesses who opt for an energy efficient motor with a white certificate will not only be contributing to their businesses’ energy and cost savings, but the nation’s and EU’s climate change targets. What could be better?

The W22 Magnet IE4/IE5 motors can be used in applications such as cooling towers, bag filters, paper machines, paper coil winders, conveyors, pumps, looms, direct current (DC) motor replacements, extruders, compressors and fans. For further information, visit the WEG website: www.weg.net.